Product Description:

SG-RLL automatic casting furnace is our ideal equipment for special glass, ceramics and metal materials for universities, research institutes and mining enterprises, with high degree of automation, accurate temperature control, and automatic mixing of the molten material. Fully automated software, one-click automatic operation. Easy, convenient and fast installation, plug and play, you can customize the furnace size according to customer requirements, you can melt and pour 20 KG at a time, and the working temperature is 100~1700℃.

Main Functions And Features:

1.Temperature Control Mode: integrated circuit, high-power module control, double loop protection, deviation protection, over-temperature protection, break protection, over-pressure automatic pressure relief, high temperature alarm and power off, leakage protection, reliable operation;

2.Heating Elements: high quality resistance wire / silicon carbon rod / silicon molybdenum rod;

3.Observation Window: 304 stainless steel flange fixed quartz plate can be used as the observation window;

4.Mixing System: digital frequency converter can be used to adjust the speed, up and down can be lifted up and down, using electric wire rod lifting system, stable without fibrillation;

5.Material Table Structure: the use of electric hydraulic system to make the crucible table can tilt 90 degrees discharge (whole automatic);

6.Energy Saving Advantages: double-layer resistant heat insulation, furnace all use composite aluminum fiber as insulation layer, energy saving effect is 30% of the old electric furnace;

7.Furnace Structure: all using composite alumina refractory material inter-buckle assembly, reasonable and stable structure, high temperature resistance, rapid cold and heat resistance, no crystallization, no slag, no pollution, etc.;

8.Intelligent PID adjustment, micro-computer control, 30 section of programmable temperature control curve, without guard (automatic rise, drop, insulation).

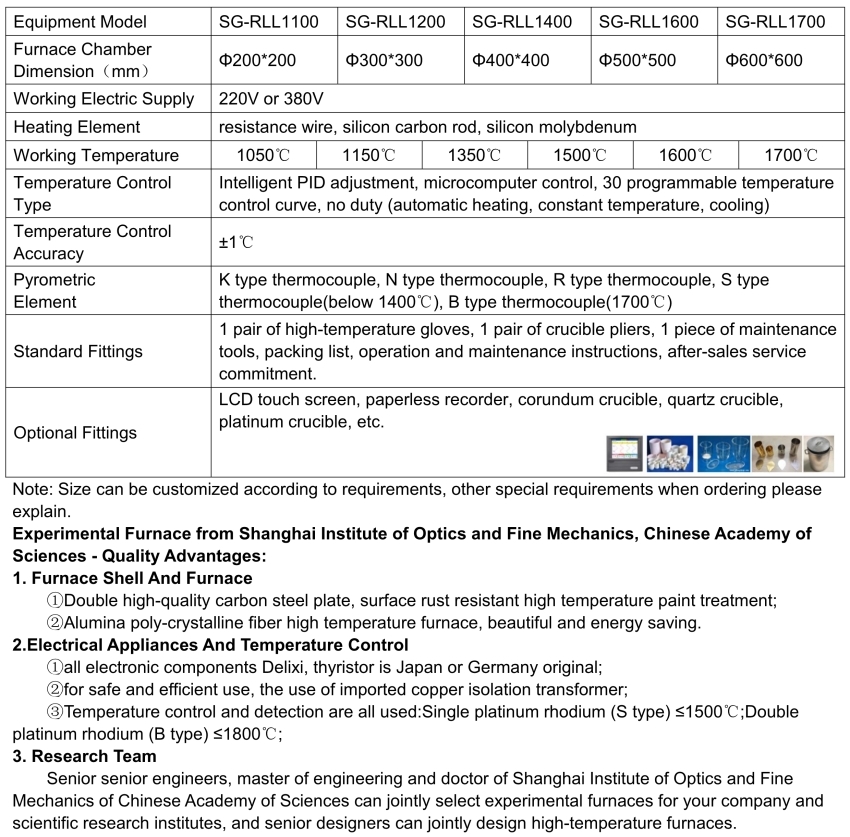

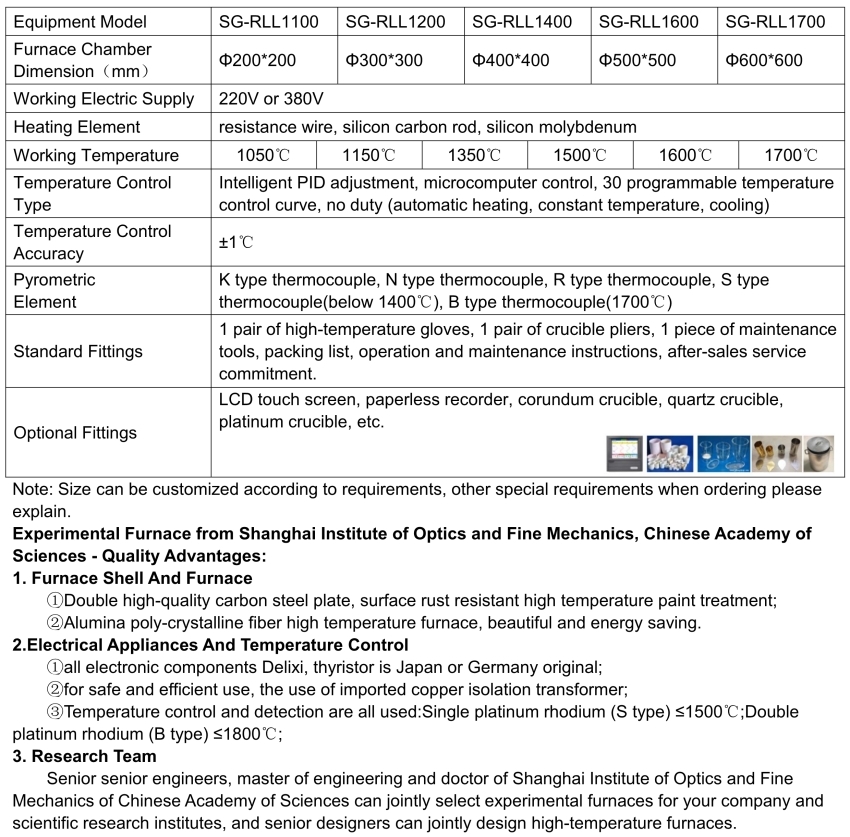

Technical Parameter:

(1) Design Power: 8-50 kW

(2) Overall Dimensions: from 600 / 600 / 1200

(3) Design Temperature: 100-1600℃ / long-term working temperature: 1600℃

(4) Rated Voltage: 380V

(5) Phase Number: 3P

(6) Frequency: 50Hz

(7) Number Of Heating Sections: according to the volume

(8) The Temperature Controller Adopts the XiaMen YuDian 518P 30 curve

(9) Heating Time Of The Empty Furnace: 1.5h

(10) Air Furnace Loss: 8%

(11) Temperature Control Accuracy: ± 1℃

(12) Temperature Control Mode: integrated circuit, high-power module control, double loop protection(deviation protection, over-temperature protection, leakage protection, break protection, over-pressure protection, super-fluid protection, etc.), electric furnace long-term work stability and high reliability.

(13) Temperature Measurement (temperature control) points: 1

(14) Thermocouple type: S / B type

(15) Material Table: 50 Kg

(16) Furnace Wall Temperature: 38℃

(17) Heating Material: silicon-carbon rod / silicon-molybdenum rod

(18) Observation Window: the 304 stainless steel flange fixed quartz plate is used as the observation window

(19) Mixing System: using digital frequency converter to adjust the speed, up and down can be lifted by electric wire rod lifting system stable without shaking.

(20) Lift Mode: electric hydraulic lifting system

(21) Lift Rate: the drop time is about 35 seconds, the backward time is about 20 seconds, and the dump time is about 20 seconds

(22) Material Table Structure: using the electric hydraulic system to make the crucible table can tilt 100 degrees to discharge (the whole process of automatic)

(23) Energy Saving Advantages: double-layer resistant heat insulation, furnace all using composite aluminum fiber as insulation layer energy saving effect is 30% of the old electric furnace.

(24) Furnace Structure: all made of composite alumina refractory inter-buckle assembly, reasonable and stable structure, high temperature resistance, cold and heat resistance Resistant to emergency, cold and hot, no cracks, no crystallization, no slag, no pollution, etc.

GL Tube-Type Furnace

GL Tube-Type Furnace

XL Box-Type Furnace

XL Box-Type Furnace

XQL Atmosphere Furnaces

XQL Atmosphere Furnaces

JSL Pit-Type Furnace

JSL Pit-Type Furnace

SJ Sintering Furnace

SJ Sintering Furnace

SJL Elevator Type Furnace

SJL Elevator Type Furnace