Equipment Purpose:

An induction melting furnace is a type of high-temperature heating equipment,which used to melt solid metals into liquids and adjust their qualities. It is utilized for modern metallurgical processes such as melting and smelting metal materials, as well as precision casting, under vacuum or protective atmospheres.

Main Technical Parameters:

1. Input Power: Three-phase 380V/50Hz

2. Heating Power Supply: Medium-frequency power supply

3. Heating Power: 20KW

4. Oscillation Frequency: 1500-4000Hz

5. Operating Temperature: ≤2000℃

6. Crucible Capacity: 0.5-1kg

7. Ultimate Vacuum: 6.67×10-3Pa (cold state, no load)

8. Crucible: Graphite Crucible (20 graphite crucibles supplied with the furnace)

9. Temperature Control Method: Power control≤1200℃,imported infrared thermometer control ≥1200℃

10. Crucible Rotating Device: Coil can swing and tilt for pouring, maximum tilt angle of 105°, observation window Dia 100

Equipment Structure And Function Description:

The furnace door adopts a double-layer stainless steel water jacket flat plate diverter structure, welded with the flange as a whole. Both the inner and outer walls are polished. The furnace door is equipped with cooling water inlets and outlets, observation windows, etc. The furnace door and the furnace body are locked using a quick-release bolt handwheel for easy operation.

The furnace body adopts a double-layer stainless steel water jacket structure, welded with the front flange and bottom head to form a cylindrical structure. A dovetail sealing groove is opened on the front flange plane, sealed with an O-ring silicone rubber seal. The side of the furnace body is equipped with cooling water inlets and outlets, vacuum pumping ports, rotating electrode installation holes, automatic filling and venting interfaces.

Vacuum System:

The vacuum system employs a two-stage pump configuration, consisting of a diffusion pump, mechanical pump, high-vacuum butterfly valve, charging valve, venting valve, vacuum pressure gauge, and composite vacuum gauge. The connection between the vacuum piping and the pumps uses metal bellows to reduce vibration. The vacuum level is displayed by a composite vacuum gauge.

Induction Melting Device:

The induction melting device consists of a rotating electrode and an induction coil. The rotating electrode is made by processing and welding commercial pure copper tubing, divided into inner and outer electrodes, with manual rotation. A busbar is set at the outer end of the electrode, connected to the power cabinet through copper bars. The induction coil is customized from high-quality water-cooled commercial pure copper tubing.

Control And Power Supply:

The power supply adopts a medium-frequency power supply equipped with indicators for medium-frequency power, voltage, and frequency, providing easy and quick operation.

The system is equipped with safety interlock protection, including over-temperature power-off protection, cutting off water and power and other function.and necessary audible and visual alarms and protections.Not only these, but also set the necessary sound and light alarm and protection.

Water Cooling System:

The water cooling system consists of a stainless steel water manifold with individual regulating valves. After entering the water manifold, the cooling water is sent to units requiring cooling water, such as the furnace door, furnace body, rotating electrode, sensors, and vacuum pumps, through individual circulating cooling circuits, then collected and recycled after cooling. The main water manifold piping is equipped with an electrical contact pressure gauge, which provides audible and visual alarms and cuts off the power supply in case of water failure. The water pipes use transparent plastic hoses, connected to the water manifold through stainless steel connectors for branching and circulating cooling. Manual valves can adjust the water flow of each circuit (water source to be provided by the user).

GL Tube-Type Furnace

GL Tube-Type Furnace

XL Box-Type Furnace

XL Box-Type Furnace

XQL Atmosphere Furnaces

XQL Atmosphere Furnaces

JSL Pit-Type Furnace

JSL Pit-Type Furnace

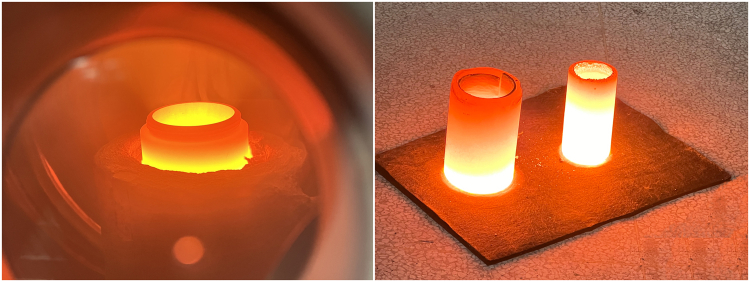

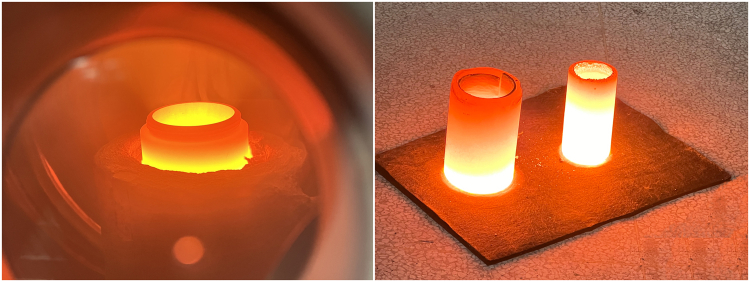

SJ Sintering Furnace

SJ Sintering Furnace

SJL Elevator Type Furnace

SJL Elevator Type Furnace