Equipment Description:

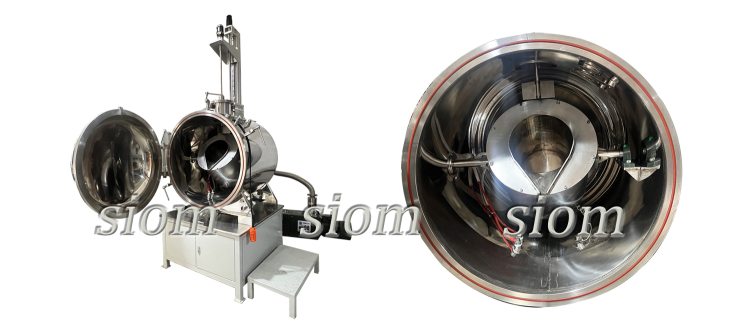

SG-ZP vacuum induction melting furnace is a modern smelting equipment for high temperature alloy, precision alloy, special steel and some non-ferrous metals and alloy materials, using the principle of medium frequency induction heating, melting smelting, casting various shapes of ingot mold, precision casting, etc.

Main Functions And Features:

1. The vacuum melting chamber is composed of furnace body, furnace cover, furnace door, insulation device, temperature measuring system, optional ramming mechanism/tilting mechanism/charging system/lifting system. This equipment is heated by medium frequency induction, and there is a spiral tubular induction coil inside the furnace body. The lid is turned horizontally open. The furnace body and the furnace cover are double-layer water flow structure, and the inner wall is made of 304 stainless steel, which is finely polished and made of large area, so it can easily remove condensed water vapor and dirt stuck during melting.

2.The furnace cover can be optional auxiliary feeding device, in order to add alloy material during melting. The pre-prepared alloy material can be loaded into the hopper before vacuuming, and the material can be dropped into the hopper through the vacuum seal handle under vacuum, and then sent into the crucible through the hopper. The observation window is equipped with heat-resistant quartz glass, or a movable stainless steel baffle can be installed under the glass, and the smelting situation in the furnace can be observed at any time by turning the handle. Please wear protective glasses when observing.

| Model | SG-ZP1700 | SG-ZP1800 | SG-ZP2200 |

| Working Electric Supply | 3-Phase 380V |

| The Highest Temperature | 2200℃ |

| Rated Power | 35KW~220KW |

| Supply Frequency | 1000~4000HZ |

| Limit Vacuum Degree | 6.7*10-3Pa(Cold Status,No-Load) |

| Crucible Capability | 0.48~350L |

| Power Supply | IGBT |

| Electrical Control System | LCD touch screen display, so that the program setting is faster, the equipment running state is more intuitive, setting data and operation are graphic interface, easy to operate; For data storage and output, data can be copied to the computer for long-term storage through the USB interface, and multiple programs can be stored. All monitoring values can be displayed at the same time: current, voltage, power, frequency, etc. |

| Heating Element | Induction Coil, Graphite Crucible |

| The equipment size can be customized according to customer requirements and the corresponding vacuum system can be selected. |

GL Tube-Type Furnace

GL Tube-Type Furnace

XL Box-Type Furnace

XL Box-Type Furnace

XQL Atmosphere Furnaces

XQL Atmosphere Furnaces

JSL Pit-Type Furnace

JSL Pit-Type Furnace

SJ Sintering Furnace

SJ Sintering Furnace

SJL Elevator Type Furnace

SJL Elevator Type Furnace