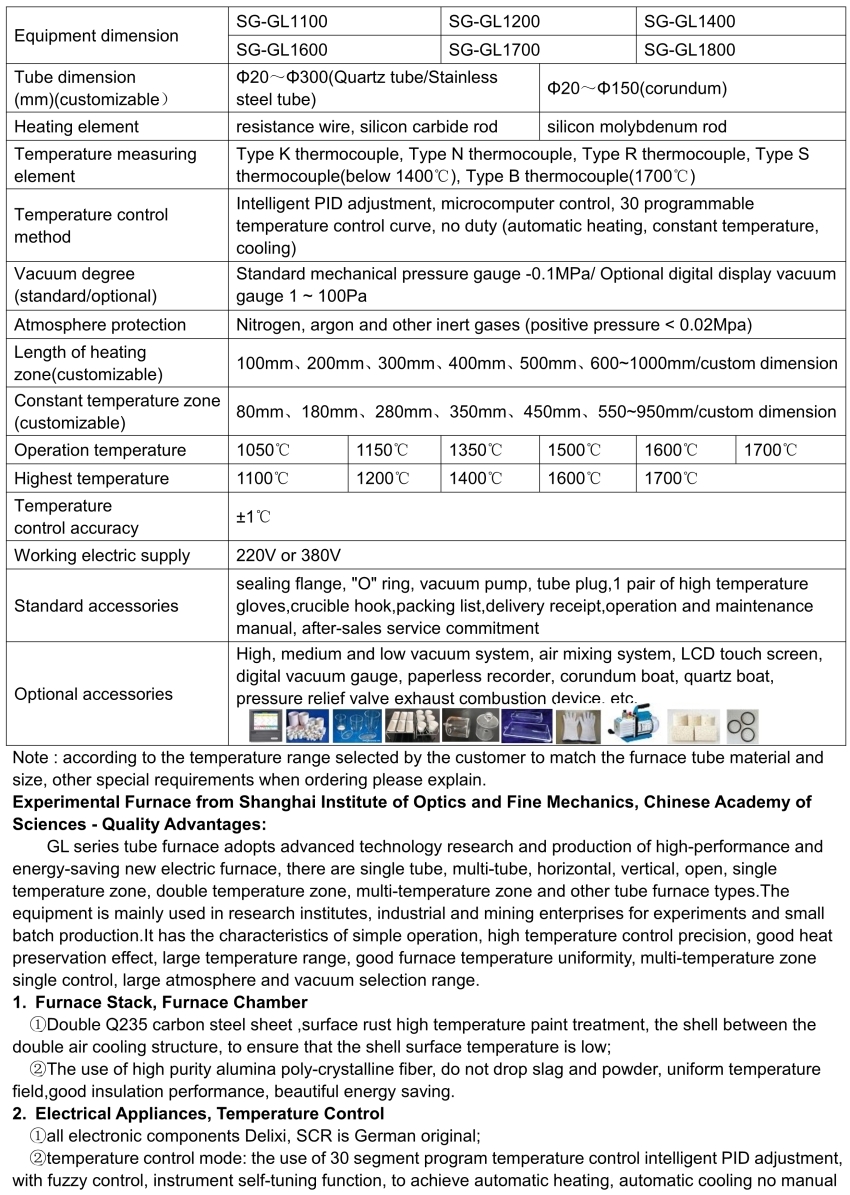

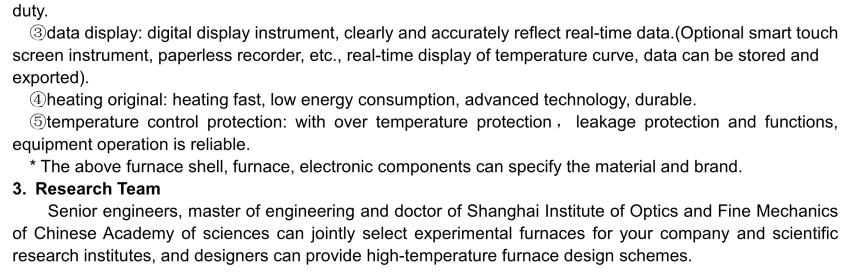

Product Description:

The furnace chamber is constructed using alumina poly-crystalline fiber solidification, with a customizable working temperature range to suit different experimental needs. Heating is achieved through the use of resistance wire, silicon carbon rods, or silicon molybdenum rods, controlled by a programmable temperature control system. The ends of the furnace tube are sealed with stainless steel flanges, allowing for vacuum pumping and gas introduction. The furnace chamber structure can be optionally configured as either open or closed.

The bonded vertical tube furnace is equipped with a lifting platform at the bottom, and the material platform surface can be manually adjusted to ensure levelness. It also comes with a strong magnetic level gauge, spare stainless steel material platform plates, and stainless steel support rods.

Temperature Control: Precise temperature control is possible, ensuring that the samples reach the desired temperature during the heating process.

Simple Structure: The tube furnace features a relatively simple structure, making it easy to operate and maintain, which has led to its widespread application in industrial production.

High Safety: The equipment is equipped with comprehensive safety protection measures, including high-temperature alarms and electrical protection, to ensure the safety of personnel and equipment during operation.

The bonded vertical tube furnace is widely used in industries such as metallurgy, glass, ceramics, electronics, and chemicals. It can be applied to processes such as annealing, heat treatment, sintering, melting, and more.

GL Tube-Type Furnace

GL Tube-Type Furnace

XL Box-Type Furnace

XL Box-Type Furnace

XQL Atmosphere Furnaces

XQL Atmosphere Furnaces

JSL Pit-Type Furnace

JSL Pit-Type Furnace

SJ Sintering Furnace

SJ Sintering Furnace

SJL Elevator Type Furnace

SJL Elevator Type Furnace