1. Input voltage of power supply: 3-phase 50Hz 380V+10%

2. Power Input Current: AC170A

3. DC Voltage of Power Supply: DC500V

4. DC Current of Power Supply: DC200A

5. Intermediate Frequency Voltage of Power Supply: AC250V

6. Intermediate Frequency Power of Power Supply: 90Kw

7. Electric Furnace Cold Limit Vacuum: 6.67 x 10-3Pa

8. COLD PRESSURE LIFT RATE OF ELECTRIC FURNACE: <30Pa/h

9. Maximum Temperature: <2000 C

10. Cooling water flow: 15T/h

11. Load working parameters: pre-vacuum for 30 minutes, high vacuum preheating for 15 minutes (open valve), high vacuum for 30 minutes, heating for 20 minutes, 500 30 minutes, 1000 60 minutes, 2000.

II. Structure and Performance Description

SG-ZP vacuum induction melting furnace is composed of vacuum furnace body, medium frequency power supply, vacuum system, cooling system and electrical control system.

1. furnace body

Furnace shell diameter 800*high 1200mm, diffusion pump KT-300, mechanical pump 2X-70

The vacuum furnace body is a vertical water-cooled double-wall drum, the bottom of the furnace is an arch and water-cooled, and the left side of the furnace body is the feeding device of induction coil. The medium frequency power supply feeds the electric energy into the induction coil through the external cable and the feeding electrode. The vacuum system is placed on the central line on the right side of the furnace. The induction coil used for smelting is placed at the back of the center of the furnace, and the tilting of the induction coil is completed by the hydraulic system. The front end and lower part of the induction coil is the ingot chamber, and there is a platform for placing the ingot mould. The ingot removal is completed by the hoisting crane in the workshop.

The cover of vacuum induction furnace is a double-wall water-cooled arched cover. A tamping rod, a rotating observation window and an alloy charging hopper are arranged on the furnace cover. There is a sealing ring on the flange surface of the furnace mouth. When vacuum is pumped, the furnace cover is sealed by atmospheric pressure. A rotating observation window is arranged on the cover of the electric furnace, which can clearly observe the condition in the crucible and in the pouring process. The rotating observation window consists of a blind plate and two quartz glass lenses. When one of them is contaminated by metal vapor deposits, the rotating observation window can be installed outside the furnace to rotate 60 degrees, then another clean lens appears. When the observation window is not in use, the blind plate can be moved under the observation window to prevent quartz glass from being exposed to thermal radiation for a long time. The electric furnace is equipped with an alloy charging hopper. Several elements are added in the melting process without damaging the vacuum.

The opening and closing of the furnace cover is completed by a hydraulic lifting device, which can lift the top of the furnace cover for a certain distance, and then rotate the furnace cover manually. The lifting position is protected by double limit switch.

2. Medium Frequency Power Supply

The intermediate frequency induction coil is made of special-shaped copper tube, and the melting crucible is made of pure graphite.

Medium frequency power panel for touch screen display; built-in PLC control settings. The adjustment of intermediate frequency power is accomplished by a regulator potentiometer, and the panel is equipped with a fault indicator lamp. Once under-water pressure or over-current or short circuit occurs, the system can stop working immediately to ensure the safety of the equipment. The medium frequency power supply is placed on the operating platform for easy operation and observation. The power cabinet is fed by a water-cooled cable to the isolation transformer, and the isolation transformer and capacitor are installed in one. Inside the shelf, it is placed under the leading end (electrode) of the inductor and connected with the electrode device by water-cooled copper bars.

3. Vacuum system

The vacuum system of the vacuum induction melting furnace consists of a 2X-70 mechanical pump, a KT-300 oil diffusion vacuum pump, a vacuum pipeline and a pneumatic baffle valve. A stainless steel filter screen is installed at the suction port of the furnace body to protect the vacuum machinery, and an electromagnetic pressure differential valve is installed at the pump port of the 2X-70 mechanical pump to prevent the mechanical pump oil from returning to the furnace during a sudden power outage. Vacuum pressure gauge, vacuum gauge seat, exhaust valve and protective gas charging valve are installed on the vacuum unit. Seamless steel pipes are used for vacuum pipes. The KT-300 oil diffusion pump is equipped with a water-cooled cold trap and a pneumatic baffle valve. The vacuum pipeline is equipped with pneumatic baffle valves. There are electrical interlocking devices between the valves to prevent misoperation. The vacuum measurement in the furnace is measured by a digital composite vacuum gauge.

4. Cooling system

Vacuum induction melting furnace has a centralized cooling water supply and drainage device. The total cooling water supply device is equipped with multiple ball valves for the distribution of cooling water, and an electric contact water pressure meter. Once an underwater pressure system occurs, the sound and light alarm will be issued immediately and the system will stop running. The cooling water of each passage is collected into a small water tank and discharged. The water tank is open. The temperature of each passage of cooling water can be measured by hand and the flow rate of each passage of cooling water can be observed. Users only need to connect the main supply and drainage pipe of cooling water to the main inlet and outlet of the vacuum furnace.

5. Electrical Control System

With LCD touch screen display, the program settings are faster, the running state of the device is more intuitive, the settings and operations are graphical and text interfaces, easy to operate; for data storage and output, data can be copied to the computer through USB interface for long-term storage, and multiple programs can be stored.

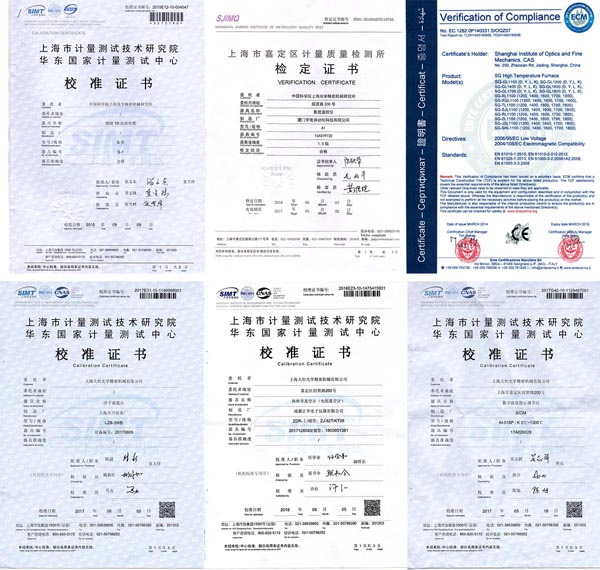

Quality Advantages of Experimental Furnace of Shanghai Institute of Optical Precision Machinery, Chinese Academy of Sciences:

Senior engineer, master of engineering and doctor of Shanghai Institute of Optics and Precision Machinery, Chinese Academy of Sciences, can provide high temperature furnace design scheme for your company and research institute.