Product Description:

Vacuum graphite has a high vacuum/inert atmosphere,and ultra-high temperature characteristics,which is widely used in quartz product,crystalline ceramics,composite material ,high-temperature alloy and other fields.

High temperature purification, powder metallurgy materials, tungsten carbide and other products of high temperature sintering in the whole process control can be completed by programmable PLC, equipment with chain protection, manual or automatic switching.There are upright and horizontal types of furnaces.

Construction Introduction:

Furnace is consist of the furnace door,furnace shell,heat shield,calorifier,stock platform and the others.

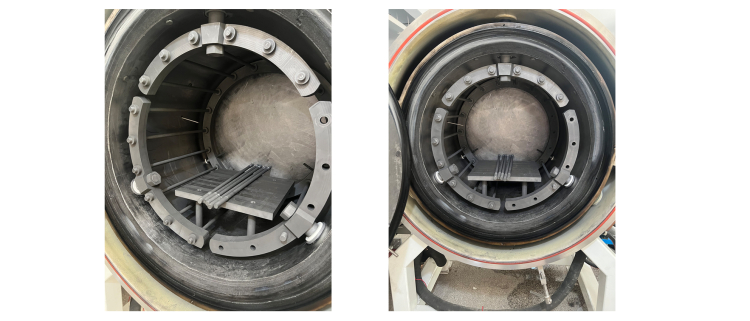

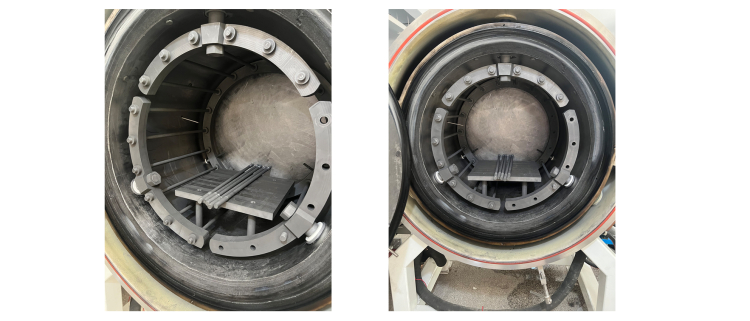

The furnace door is welded together using a double-layer head and flange plate, employing a double-walled structure with circulating cooling water inside both the inner and outer heads for cooling. The inner head of the furnace door is made of stainless steel plate.

The furnace shell's inner and outer shells are made of stainless steel plate, featuring a double-walled water-cooled structure;the furnace body is equipped with electrode extraction devices, thermocouple temperature measurement devices, as well as gas inlet and exhaust holes;the furnace door is connected to the furnace body via door hinges and opens on the side;the furnace door is equipped with an observation hole and a door pressing device.

The heat shield is made of graphite and carbon felt materials, adopting a circular structure. From the inside out, the first layer is composed of hard graphite felt, while the subsequent layers utilize graphite felt as thermal insulation material.

The heater also adopts a circular structure, installed around the circular thermal shield to form a circuit. The heater uses a graphite plate as the heating element, which is easy to dismantle and repair. The insulating materials of the heater are all made of high-purity boron nitride. The material support frame is processed from graphite.

Vacuum and Gas Filling System: The vacuum system consists of Roots pumps, mechanical pumps, high-vacuum pneumatic flap valves, vacuum piping, vacuum gauges, pressure gauges, and composite vacuum meters. The gas filling device (excluding gas drying, gas filtering, gas leak detection devices, and tail gas treatment systems) mainly consists of gas filling valves, float flowmeters (or optional mass flowmeters), gas filling piping, and exhaust valves. It is used to meet the argon and nitrogen atmosphere requirements of the process, with a maximum filling pressure of ≤0.03MPa (slight positive pressure, gauge pressure).

Water Cooling System: It comprises a main water inlet pipe, a main water outlet pipe, multiple branch inlet pipes, multiple branch outlet pipes, valves, and pressure gauges. Cooling water enters the furnace shell, furnace door, electrodes, diffusion pumps, and other areas requiring cooling through the main inlet pipe and respective branch inlet pipes, then collects into the main outlet pipe via the branch outlet pipes for discharge. An electric contact pressure gauge is installed on the main inlet pipe. When the main inlet pressure falls below the set value, the control system will trigger an audible and visual alarm and automatically cut off the heater's power supply. Each branch inlet pipe is equipped with a valve to adjust the flow rate of cooling water in a single circuit (water source needs to be provided or a chiller can be optionally equipped).

The Main Technical Parameter:

1. heat region:first region

2. The highest temperature:1700℃

3. Working temperature:≤1650℃

4. Effective working area(mm):400×400×400(Depth×width×height)

5. Limitation Vacuum Degree:≤50Pa(cold, no-load condition.)

6. Vacuum System Configuration: Roots Pump + Mechanical Pump

7. Gas Charging Method: Automatic gas charging. The vacuum pump stops working after the vacuum reaches 50pa, and the inlet valve automatically opens to charge the gas to 6000pa, followed by pressure-holding sintering. Gas Medium: Nitrogen, Argon (to be used under positive pressure ≤0.03Mpa)

8. Temperature Control Mode: Kunlun Touch Screen LCD + Japanese Mitsubishi PLC Control

9. Temperature Control Range: Room Temperature to 1650℃, using Tungsten-Rhenium Thermocouple

10. Temperature Control Accuracy: ≤±1℃

11. Heating Rate: 1-10℃/min

GL Tube-Type Furnace

GL Tube-Type Furnace

XL Box-Type Furnace

XL Box-Type Furnace

XQL Atmosphere Furnaces

XQL Atmosphere Furnaces

JSL Pit-Type Furnace

JSL Pit-Type Furnace

SJ Sintering Furnace

SJ Sintering Furnace

SJL Elevator Type Furnace

SJL Elevator Type Furnace