Performance Introduction:

Silicon nitride high-temperature sintering furnace is an experimental device commonly used in fields such as ceramic sintering and powder metallurgy. It is specifically designed for sintering special materials under a gas pressure of ≤9.8Mpa at high temperatures and pressures. Widely applied in the specialty materials industry, it is used for sintering EC ceramics (such as silicon carbide, zirconia, alumina, silicon nitride, etc.) and metallic materials (such as cemented carbides) under high-pressure protective atmospheres. Suitable for testing and mass production in universities, research institutions, and industrial and mining enterprises, it helps increase the sintering density of materials and improve their mechanical properties. It can be used for tools, rotors of turbochargers, and engines. Silicon nitride and ultra-high-temperature alloy materials sintered in gas pressure furnaces are suitable for making corrosion-resistant, high-temperature-resistant mechanical parts.

Structural Overview:

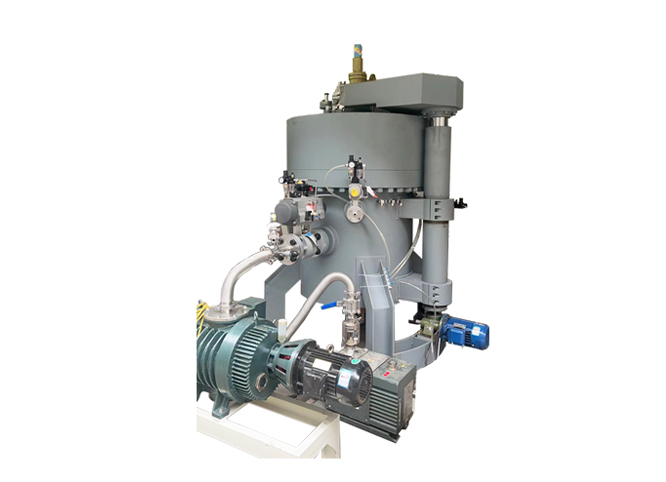

Sintering furnace mainly consists of a furnace body, heating system, water cooling system, vacuum system, gas filling and pressure system, and temperature control system.

The furnace body adopts a double-layer water-cooled structure with water cooling in the middle.

The insulation material inside the furnace can be carbon felt, graphite, molybdenum sheets, and stainless steel. The heating elements are graphite rods/plates, molybdenum strips/wires, and the inner layer is a pressure vessel. The furnace side is equipped with interfaces for gas inlet/outlet, vacuum pumping, thermocouples, pressure sensors, safety valves, electrodes, etc.

Cooling water enters through the main pipe and is distributed to various parts of the furnace that require cooling through branch pipes, then collected and discharged through the main return water pipe. Each cooling water path has a manual valve to adjust the flow of cooling water as needed. A cooling water detection device is installed on the water inlet pipe. When the water pressure is too low or there is no cooling water flow, the control system will sound an audible and visual alarm and automatically cut off the heater power through the electrical control interlock function.

The vacuum system (mechanical pump or diffusion pump unit) can be selected based on process requirements.

It consists of automatic detection, manual control for pressurization and depressurization, and safety devices such as overpressure and audible-visual alarms. The furnace is equipped with a pressure limit and an automatic exhaust safety valve. When the furnace pressure exceeds a certain value, the safety valve automatically exhausts to stabilize the furnace pressure control.

Equipment Parameter:

| No. | Item | QYL2000(customizable) |

| 1 | Rated Power | provisional 120KW |

| 2 | Electric Furnace Voltage | 380V |

| 3 | Heat Element | The graphite heating system is of vertical structure with open cover |

| 4 | Long-Term Service Temperature | 1950℃(soaking time4-12h)(customizable) |

| 5 | Effective Heating Region | 300×300mm(diameter×height)(customizable) |

| 6 | Inflation Pressure | ≤6Pa |

| 7 | Limitation Vacuum Degree | ≤5Pa(cold status, no-load) |

| 8 | Vacuum System Configuration | Roots pump + direct connection pump |

| 9 | Temperature Control Mode | PLC+ digital temperature program temperature control instrument |

| 10 | Gaseous Medium | argon, nitrogen |

| 11 | Temperature Control Range | Tungsten baht thermocouple |

| 12 | Temperature Control Accuracy | ≤±1℃ |

| 13 | Electrical Interlocking And Display | Over temperature, over current interlock protection and alarm (sound, light)voltage, current display |

Research Team

Experienced senior engineers, holding master's and doctoral degrees in engineering from the Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, are available to assist your company or research institute in selecting the appropriate experimental furnace. Our senior designers can also collaborate with you to develop a customized high-temperature furnace design plan.

GL Tube-Type Furnace

GL Tube-Type Furnace

XL Box-Type Furnace

XL Box-Type Furnace

XQL Atmosphere Furnaces

XQL Atmosphere Furnaces

JSL Pit-Type Furnace

JSL Pit-Type Furnace

SJ Sintering Furnace

SJ Sintering Furnace

SJL Elevator Type Furnace

SJL Elevator Type Furnace