Production Description:

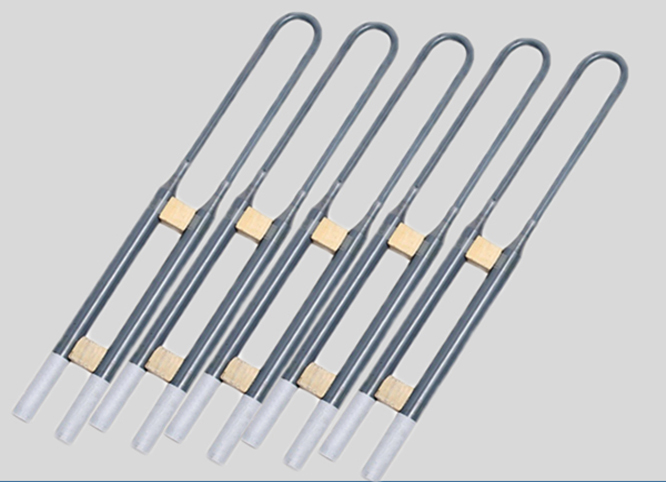

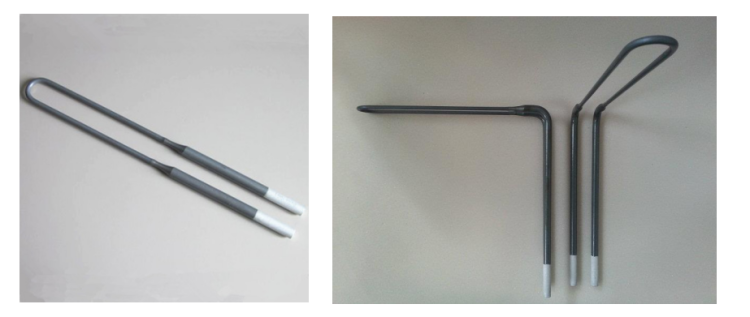

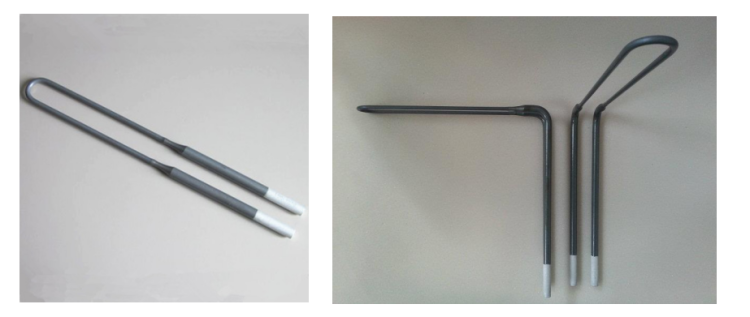

The heating element is a resistance heating element based on molybdenum silicide. Due to its small resistance, the environment used is generally low voltage and high current, so a transformer device should be used.Silicon molybdenum rod is divided into I-type silicon molybdenum rod, U-type silicon molybdenum rod, W-type silicon molybdenum rod, U-type right Angle silicon molybdenum rod, right Angle silicon molybdenum rod, special type silicon molybdenum rod.The equipment has the high temperature oxidation resistance.In the oxidizing atmosphere, the use temperature is <1700℃, the applicable temperature is 500-1700℃, and the common temperature is 1600℃.It can be used as heating element of LiNbO3, LiTaO3, TeO2, YCOB, fluoride and other crystals.

It can be used as ceramic, magnetic materials, glass, metallurgy, refractory and other industrial high temperature furnace heating elements.

Usage Characteristics:

1.The thermocouple adopts S-type single platinum rhodium thermocouple or B-type double platinum rhodium thermocouple.

2.The furnace body temperature is close to room temperature.

3.Fast heating, low energy consumption, low heat capacity, temperature control fine.

4.Silicon molybdenum rod furnace all use poly-crystalline mullite ceramic fiber, thermal shock resistance, silicon molybdenum rod insulation performance is good, cold and heat resistance, high temperature resistance.

5.Intelligent program PID control, can be programmed multiple sections of temperature, heat preservation, cooling curve, program run automatically stop, no need to watch.

GL Tube-Type Furnace

GL Tube-Type Furnace

XL Box-Type Furnace

XL Box-Type Furnace

XQL Atmosphere Furnaces

XQL Atmosphere Furnaces

JSL Pit-Type Furnace

JSL Pit-Type Furnace

SJ Sintering Furnace

SJ Sintering Furnace

SJL Elevator Type Furnace

SJL Elevator Type Furnace