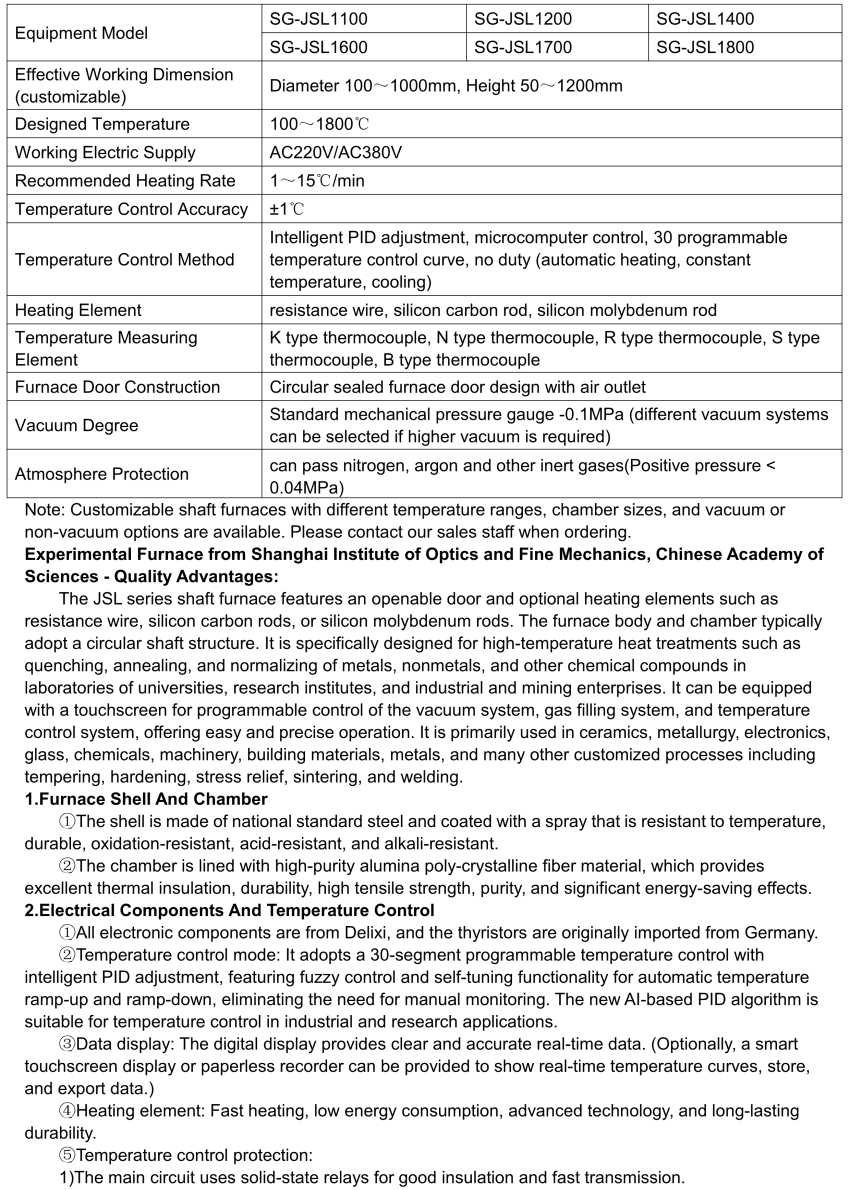

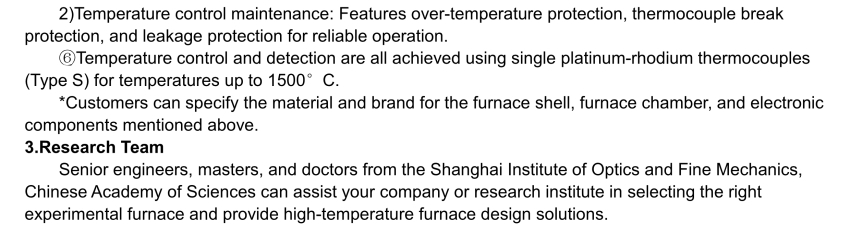

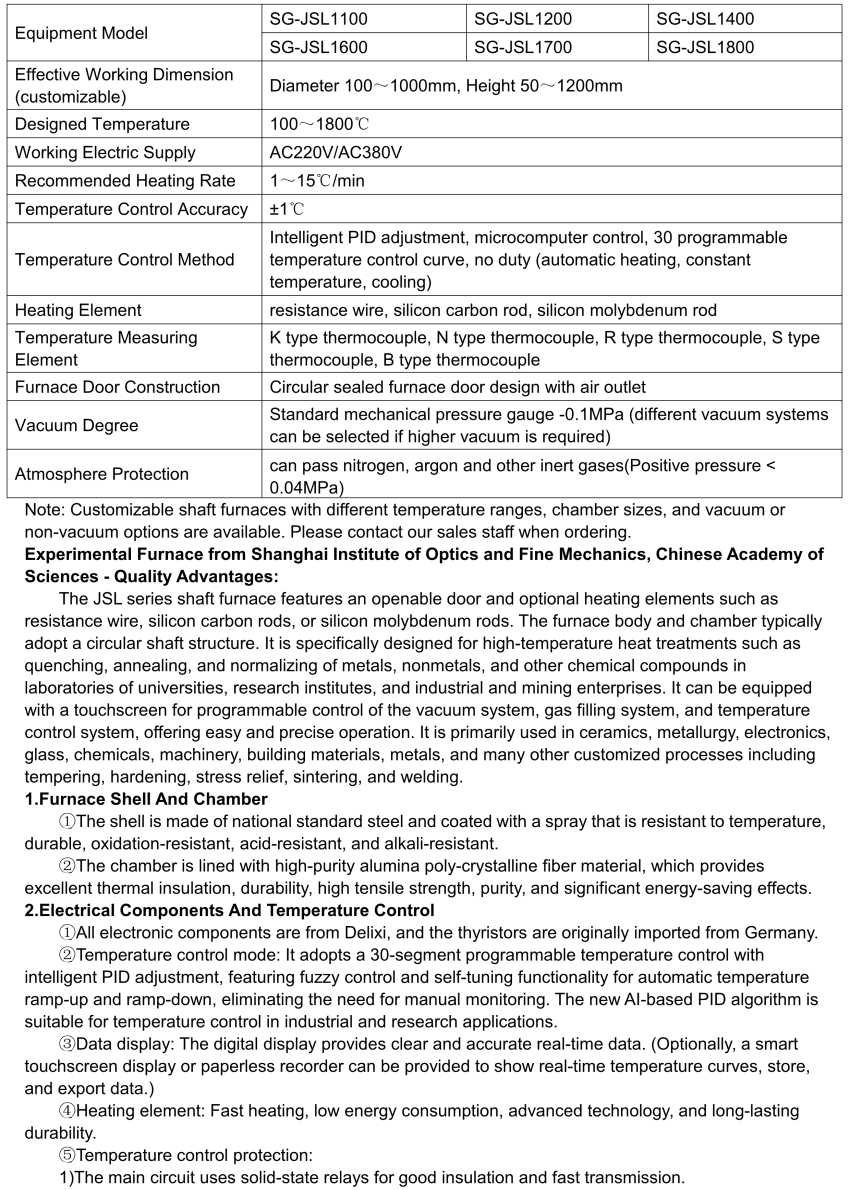

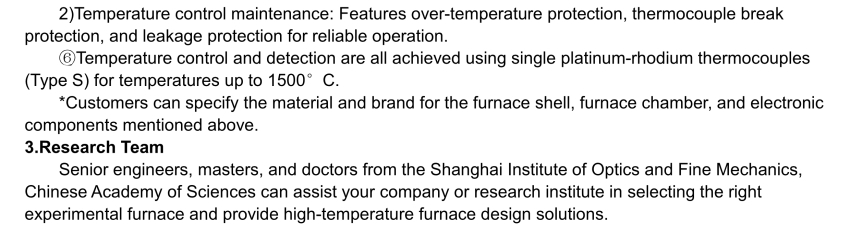

Production Description:

Elevator well type furnace uses the top-opening furnace door,which uses the resistance rod/silicon carbon rod/silicon molybdenum rod as the heating element.The equipment has the double shell structure and temperature control system.The chamber uses the alumina poly-crystalline fiber materials,which has good insulation and the ability of salving energy.The bottom elevator equipment:Φ40 lifting hole is opened at the bottom of the furnace, and the lifting adopts the screw lifting system to rotate vertically up and down, with a stroke of 300mm.

Main Uses And Application Scope:

Suitable for ceramics, metallurgy, electronics, glass, chemical industry, machinery, refractory materials, special materials, building materials, metal, non-metal, alloy materials tempering, annealing, quenching, solid solution treatment, aging treatment and other heat treatment, and its phase transition process analysis, production and development of equipment.

Main Functions And Features:

1.The furnace adopts alumina poly-crystalline fiber material, good thermal insulation performance, durable, high tensile strength, no stray ball, high purity, energy saving effect is obvious;

2. The heating element adopts resistance wire;

3.The shell can be selected Q235/304 stainless steel design, the inner tank can be selected 310S stainless steel material;

4.Turn on power off, leakage protection, high temperature alarm, to ensure the normal use of equipment.

5.Our software equipment through 485 or USB interface and computer interconnection, can achieve a single or multiple electric furnace remote control, real-time tracking, history, output reports and other functions; Paperless recording device can be installed to realize data storage and output;

6.Optional through the touch screen operation of the vacuum system, inflation system, temperature control system for program control, simple operation.

GL Tube-Type Furnace

GL Tube-Type Furnace

XL Box-Type Furnace

XL Box-Type Furnace

XQL Atmosphere Furnaces

XQL Atmosphere Furnaces

JSL Pit-Type Furnace

JSL Pit-Type Furnace

SJ Sintering Furnace

SJ Sintering Furnace

SJL Elevator Type Furnace

SJL Elevator Type Furnace