Production instruction:

Overall structure: The complete set of equipment is composed of electric furnace shell, furnace lining, heating element and electrical control system.

Furnace shell: The furnace shell is welded with Q235 carbon steel, the surface of the shell is painted at high temperature, the upper cover is opened, and the parts near the furnace door that are in contact with high temperature are made of stainless steel. Lid opening mode, electric or pneumatic lifting, manual translation.

Furnace: The furnace is made of high purity alumina fiber material by unique numerical control technology, and has strong thermal shock resistance. After the lining system is completed, a layer of high temperature curing agent is sprayed on the surface to form a layer of heat insulation wall, which increases the decent strength and thermal radiation performance of the lining, and further reduces the heat storage loss of the lining body to achieve rapid heating effect, maximize the thermal efficiency of the furnace, and has good energy saving effect. The thermal insulation material is made of high aluminum fiber refractory fiber products with good thermal insulation effect.

Heating element: The resistance wire is embedded in the furnace wall and the bottom of the furnace at 360°, which has high radiation efficiency, strengthens the heat exchange in the furnace, improves the furnace thermal efficiency, and extends the service life of the electric heating element.

Electrical control system: The electric control cabinet is located in the upper left part of the equipment, and the internal electrical components are fixed with a skeleton support structure, which is convenient for the inspection and maintenance of the components in the cabinet. And has good ventilation and heat dissipation function, improve the working environment of electrical components.

The temperature control system has PID parameter self-tuning function, the combination of expert module and control algorithm, to achieve precise temperature control, effectively inhibit temperature overshoot, with recording curve,485 communication interface connected to the computer. The over-temperature alarm system has the functions of cutting off the main circuit, sound and light alarm and automatic recovery and dissolving. When the temperature control couple breaks, the control system can automatically cut off the main circuit power supply and issue sound and light alarm.

GL Tube-Type Furnace

GL Tube-Type Furnace

XL Box-Type Furnace

XL Box-Type Furnace

XQL Atmosphere Furnaces

XQL Atmosphere Furnaces

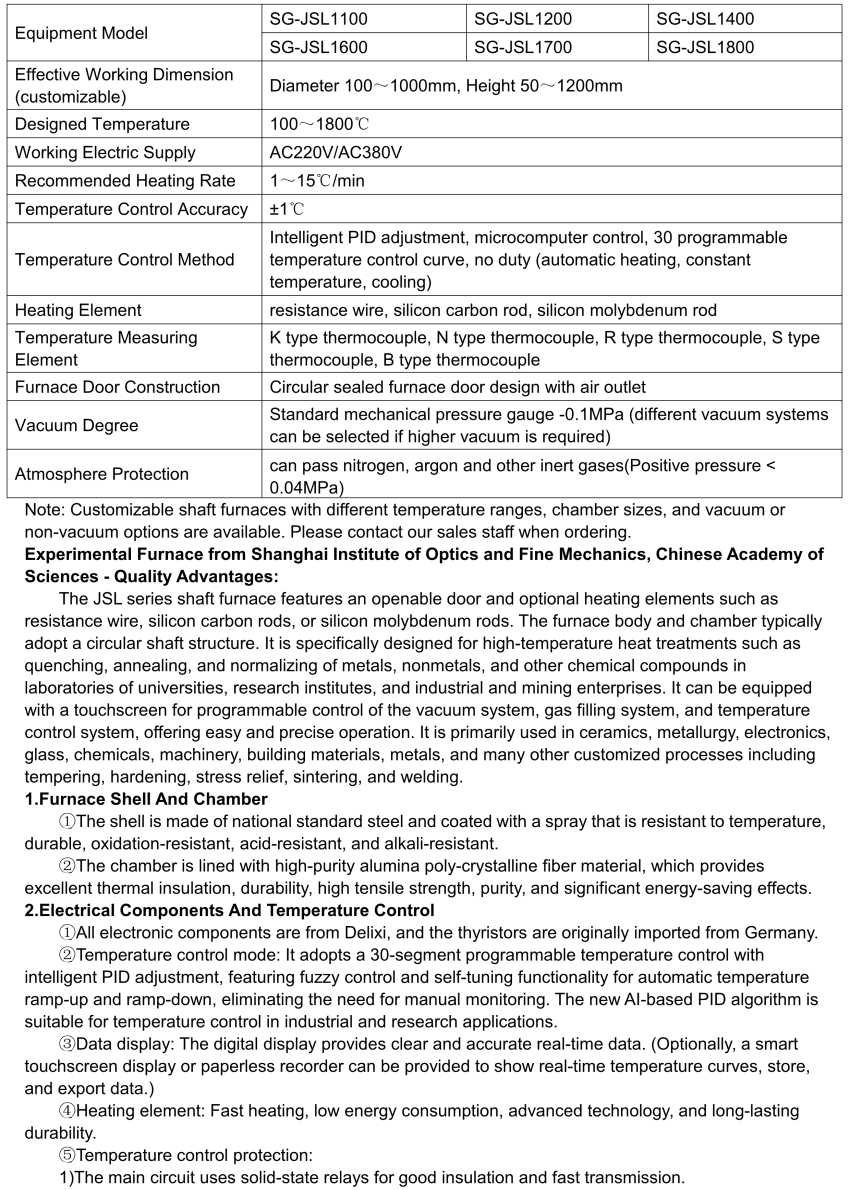

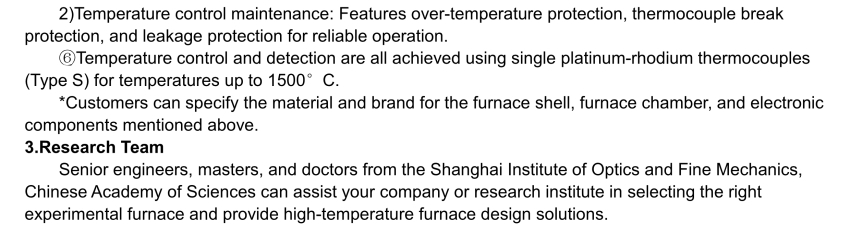

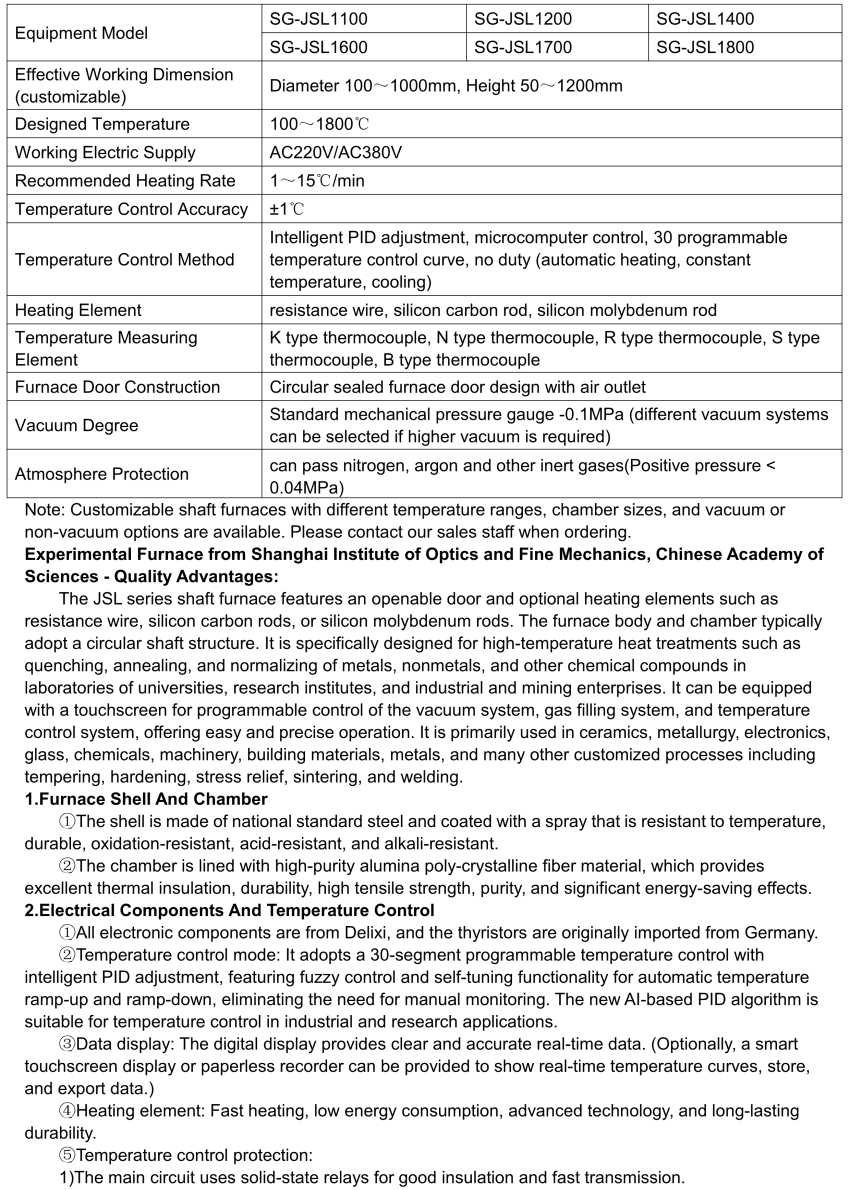

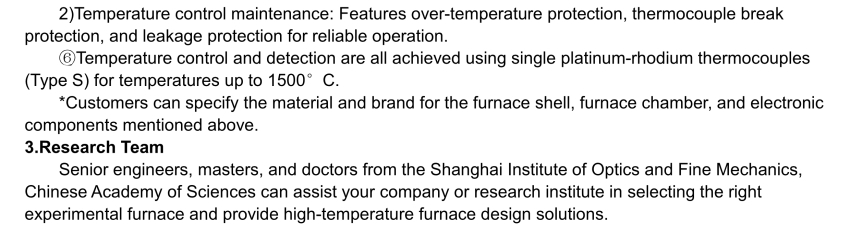

JSL Pit-Type Furnace

JSL Pit-Type Furnace

SJ Sintering Furnace

SJ Sintering Furnace

SJL Elevator Type Furnace

SJL Elevator Type Furnace