The crystal growth furnace is mainly composed of crystal lifting control system, crystal rotation control system, vacuum pump operation control system, crystal growth temperature control system and so on. Adopt driving, transmission technology and supporting devices; Sealing device made of technology and material; Adopt reliable water cooling system device; Make the rod run smoothly, no crawling and vibration. At the same time, the programmable furnace temperature control device is adopted to realize the automatic control of furnace temperature. It is equipped with a manual fast lifting device, easy to use, and is an ideal equipment for growing high melting point in artificial crystal.

Main Technology Parameter:

The furnace body adopts a double-layer 304L stainless steel water-cooled structure, and the ultimate vacuum is less than 10pa.

Lifting mechanism: using ball screw and guide rail to drag the moving platform to move in a straight line. The strain sensor is used for weighing control.

| Items | Unit | Indicated Number |

| Chamber Temperature | ℃ | ≤2100 |

| Seed Rod Increase Speed | mm/h | 0.5~60 |

| Seed Rod Speed | rpm | 0~50 |

| Seed Rod Stroke | mm | 600 |

| Limit Vacuum Degree Of Cold Furnace | Pa | 6.67x10-3 |

| Cooling Hydraulic Pressure | MPa | 0.15~0.2 |

If frequency: DSP+IGBT full air cooling digital structure, with long life, high power factor, low harmonic current, high reliability, high efficiency characteristics

System Features:

The lifting speed and rotation speed are set on the touch screen, with fault alarm, alarm record, data record, automatic power failure processing, over-pressure alarm, etc. The data record can be copied and put into the computer for analysis through the U disk. Weighing system suitable for small crystals. Multiple crystals have been successfully grown.

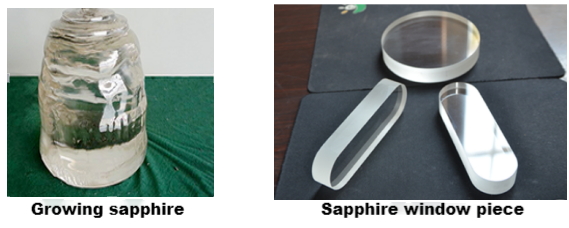

The optoelectronic Materials Instrument and Equipment Division has more than 50 years of history in the research and production of crystal materials. It is engaged in the research and development, growth and equipment development of photoelectric crystal materials. It has a variety of crystal growth methods and sets of crystal growth equipment and processes such as lifting method, descending method, flux method, zone melting method, bubble growth method, guided mode method and heat exchange method. At the same time, it also has perfect testing equipment for detecting the properties of crystal materials.

1. Provide R&D, technical support and industrialization services of crystal materials. And provide a variety of crystal growth and high temperature heat treatment equipment (crystal growth furnace, vacuum furnace, atmosphere furnace, annealing furnace and experimental furnace, etc.) R&D, technical support and industrialization.

Lifting Method And Lifting Furnace:

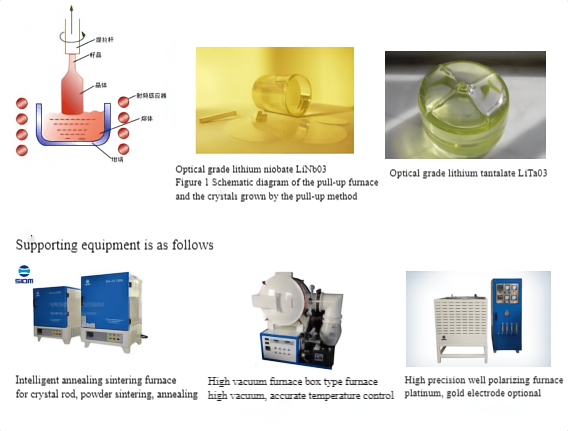

The lifting method, also known as the Czochralski method or simply the CZ method, was invented by J.Czochralski in 1917 for the purpose of lifting and growing high-quality single crystals from a melt. The Czochralski method is a commonly used technique for single crystal growth, capable of producing a variety of crystals including lithium niobate, lithium tantalate, yttrium aluminum garnet doped with magnesium fluoride, sapphire, spinel, yttrium vanadate, and more. The furnace used for growing crystals by the Czochralski method, also known as the lifting furnace, typically includes components such as a heating device, a driving device, an atmosphere control device, and a control device, among others.

Guided Mode Method:

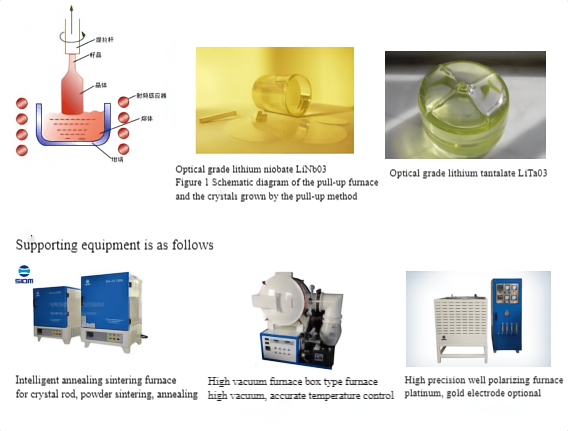

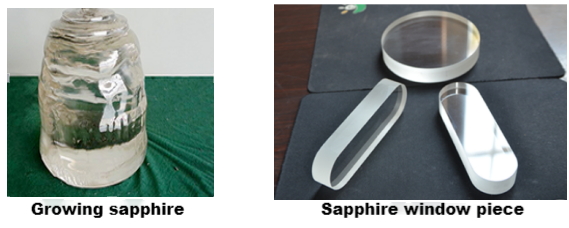

Guided mode method was proposed by Soviet scholar Stepanov around 1960, also known as Stepanov method or EFG method. This method has evolved over time and has become an important method for crystal growth. The crystal growth method has the advantages of fast crystal growth, low cost, simple crystal processing and uniform composition. Guided mode method is applied in many fields such as single crystal fiber, sapphire fairing, sapphire pipe, bar and so on.

Descent Method:

The descent method was proposed by Bridgmen in 1925, so it is also called the Bridgmen method. The principle of this method is to load the crystal raw material into the crucible, and realize the crystal growth through the relative movement of the furnace body and the crucible. The descent method is often used to grow low-melting scintillation crystals, such as bismuth germanate crystals, cesium iodide crystals, lead tungstate crystals, etc. The descending furnace generally adopts tubular design and generally has three temperature zones, namely, high temperature zone, gradient zone and low temperature zone.

GL Tube-Type Furnace

GL Tube-Type Furnace

XL Box-Type Furnace

XL Box-Type Furnace

XQL Atmosphere Furnaces

XQL Atmosphere Furnaces

JSL Pit-Type Furnace

JSL Pit-Type Furnace

SJ Sintering Furnace

SJ Sintering Furnace

SJL Elevator Type Furnace

SJL Elevator Type Furnace