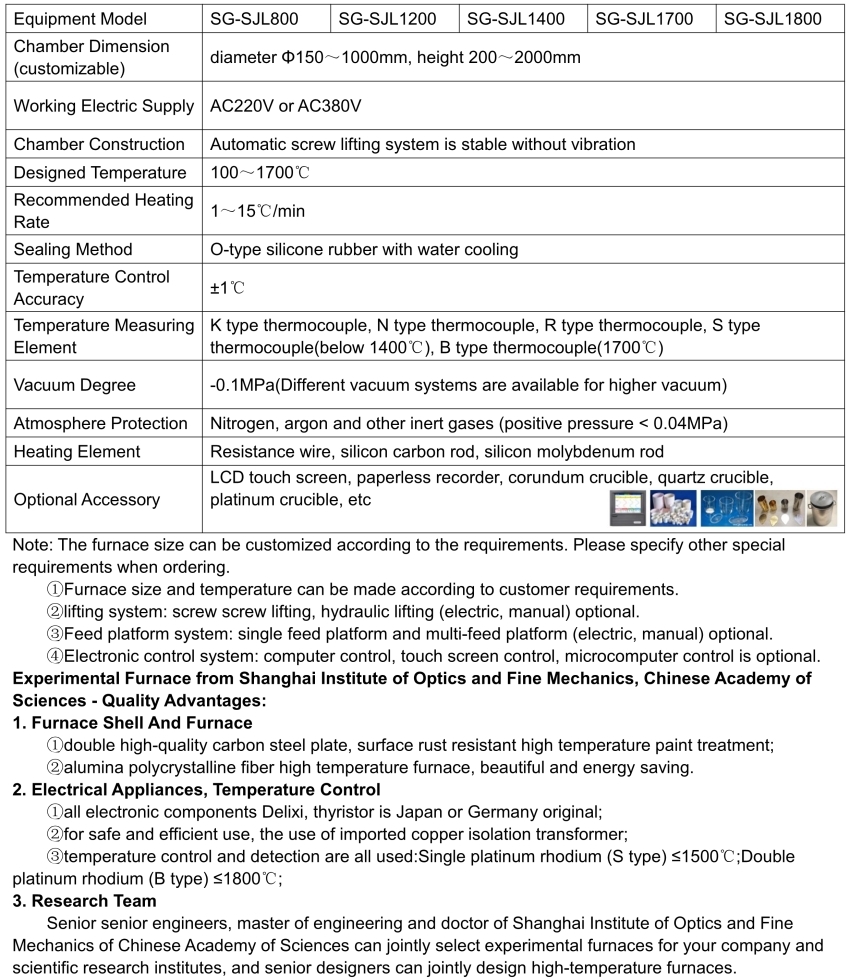

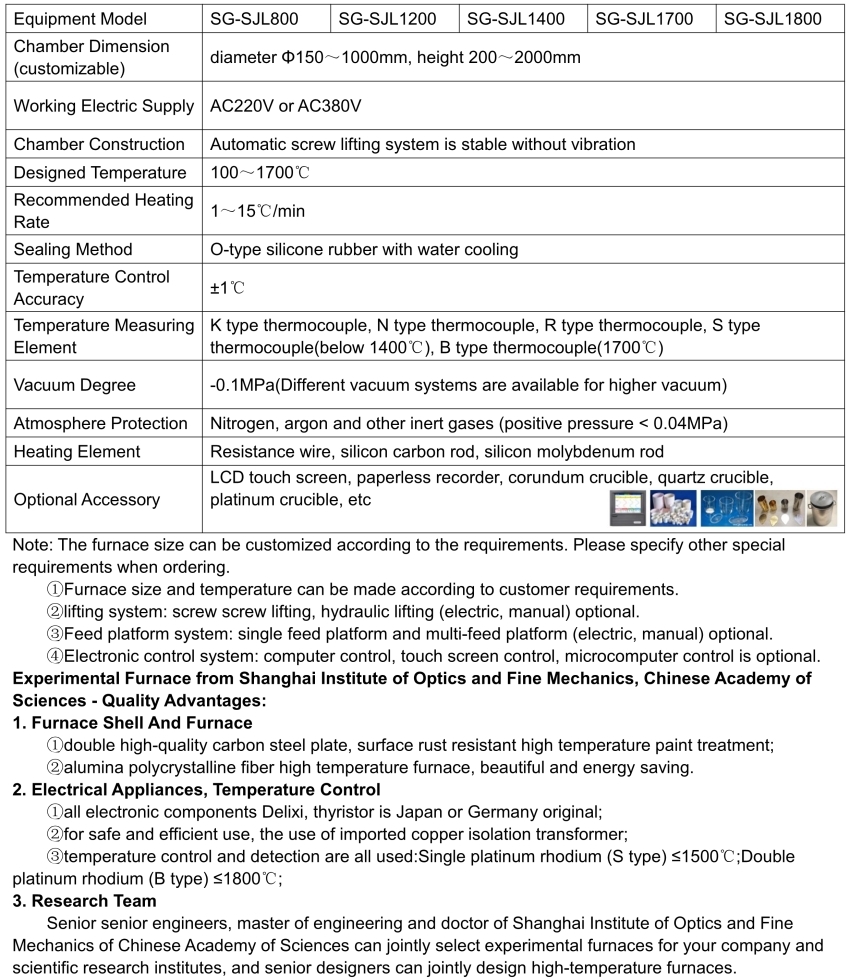

Production Description:

High temperature thermal treatment lifting furnace, with advanced and reasonable structure, beautiful appearance, the furnace is made of high purity alumina fiber material by unique CNC technology, strong thermal shock resistance, good corrosion resistance, no collapse, no crystallization, no slag, no pollution, long service life. The shell is made of high quality cold rolled steel plate, processed by advanced CNC machine tool, and adopts high quality silicon molybdenum rod as heating element. The double-layer furnace shell is equipped with air cooling system, which can quickly cool down. The furnace has the advantages of balanced temperature field, low surface temperature of furnace body, fast rising and falling temperature rate and energy saving.

The control system adopts microcomputer artificial intelligence regulation technology, with PID regulation, automatic control, self-tuning function, multi-segment program programming, and can prepare a variety of temperature, heat preservation, cooling procedures, high temperature control accuracy; Integrated module thyristor control, phase-shift trigger. The degree of automation is high, and the indicators have reached the advanced level.

Main Uses And Application Scope:

This equipment is widely used in universities, scientific research institutes, industrial and mining enterprises to do powder, electronics, metallurgy, medicine, ceramics, glass, machinery, new material development, special materials, refractory materials, building materials, chemical industry, metal sintering and metal heat treatment and other experimental and production ideal equipment.

Main Functions And Features:

1.The heating element adopts resistance wire, silicon carbon rod, silicon molybdenum rod, furnace high purity alumina fiber material, good insulation performance, durable, high tensile strength, no stray ball, high purity, energy saving effect is better than domestic fiber materials;

2.Our software equipment through 485 or USB interface and computer interconnection, can achieve a single or multiple electric furnace remote control, real-time tracking, history, output reports and other functions; Paperless recording device can be installed to realize data storage and output;

3.Over-temperature alarm and power off, leakage protection, safe and reliable operation;

4.Furnace body: electrostatic spray corrosion resistance acid and alkali resistance, furnace body and furnace isolation using air cooled furnace wall temperature close to room temperature;

5.Optional through the touch screen operation of the vacuum system, inflation system, temperature control system for program control, easy to operate, accurate;

6.Wide range of temperature control, intelligent PID adjustment, microcomputer control, 30 sections of programmable temperature control curve, no duty (automatic rise, fall, heat preservation).

GL Tube-Type Furnace

GL Tube-Type Furnace

XL Box-Type Furnace

XL Box-Type Furnace

XQL Atmosphere Furnaces

XQL Atmosphere Furnaces

JSL Pit-Type Furnace

JSL Pit-Type Furnace

SJ Sintering Furnace

SJ Sintering Furnace

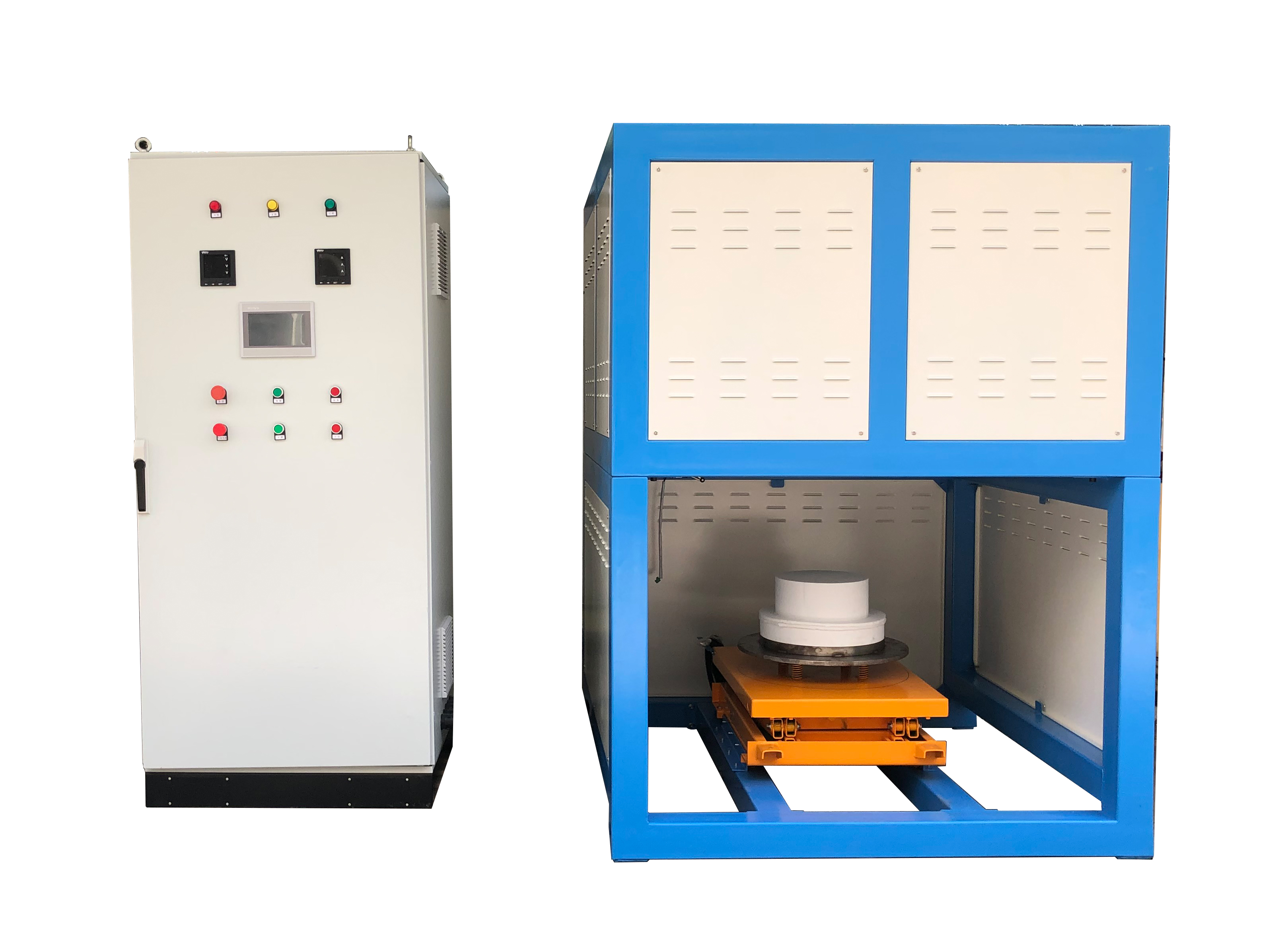

SJL Elevator Type Furnace

SJL Elevator Type Furnace