Product Description:

Sapphire annealing furnace adopts high quality silicon molybdenum rod as heating element, adopts double shell structure and intelligent temperature control system, thyristor control, phase shift trigger, furnace adopts 1800 alumina polycrystalline fiber material, double-layer furnace shell is equipped with air cooling system, which can quickly rise and drop temperature, energy saving, environmental protection, safety and reliability.

Main Uses And Application Scope:

Suitable for annealing process of sapphire wafer and sapphire crystal rod; Universities, scientific research institutes, industrial and mining enterprises for high temperature sintering, metal annealing, new material development, organic matter ash, quality testing, but also suitable for electronics, medicine, special materials and other production and experiment.

Main Functions And Features:

1.The heating element adopts high quality silicon molybdenum rod, the furnace adopts alumina poly-crystalline fiber material, good thermal insulation performance, durable, high tensile strength, greatly improve the service life;

2.Unique furnace design, durable, not collapse;

3.Our software equipment through 485 or USB interface and computer interconnection, can achieve a single or multiple electric furnace remote control, real-time tracking, history, output reports and other functions; Paperless recording device can be installed to realize data storage and output;

4.Over-temperature alarm and power off, leakage protection, safe and reliable operation;

5.Optional through the touch screen operation of the temperature control system for program control, easy to operate, accurate;

6.Wide range of temperature control, intelligent PID adjustment, microcomputer control, 30 sections of programmable temperature control curve, no duty (automatic rise, fall, heat preservation).

GL Tube-Type Furnace

GL Tube-Type Furnace

XL Box-Type Furnace

XL Box-Type Furnace

XQL Atmosphere Furnaces

XQL Atmosphere Furnaces

JSL Pit-Type Furnace

JSL Pit-Type Furnace

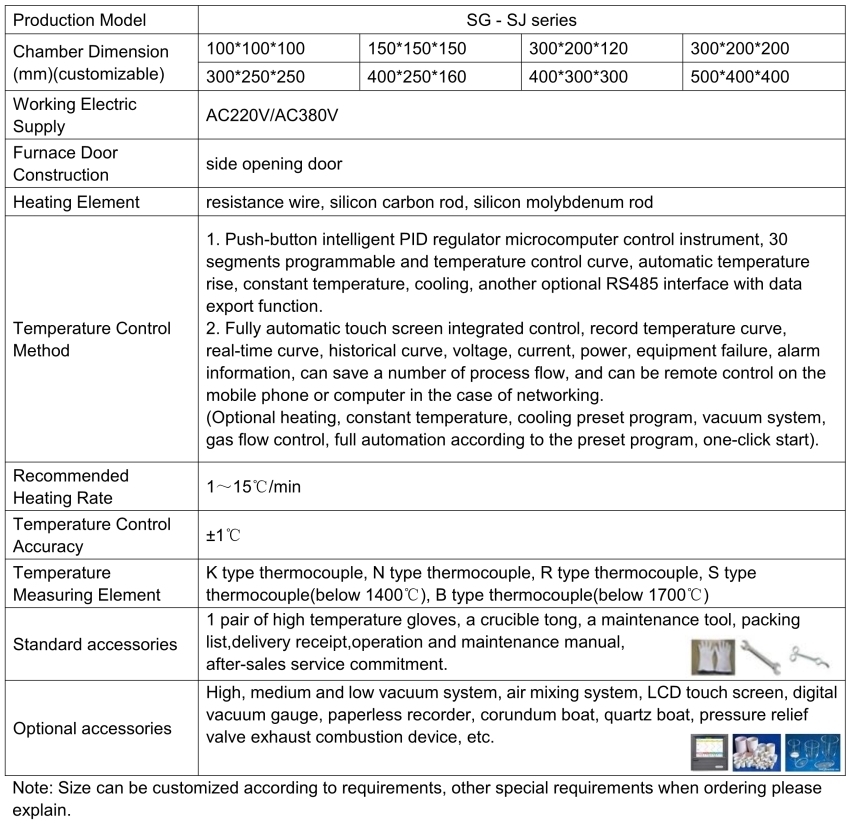

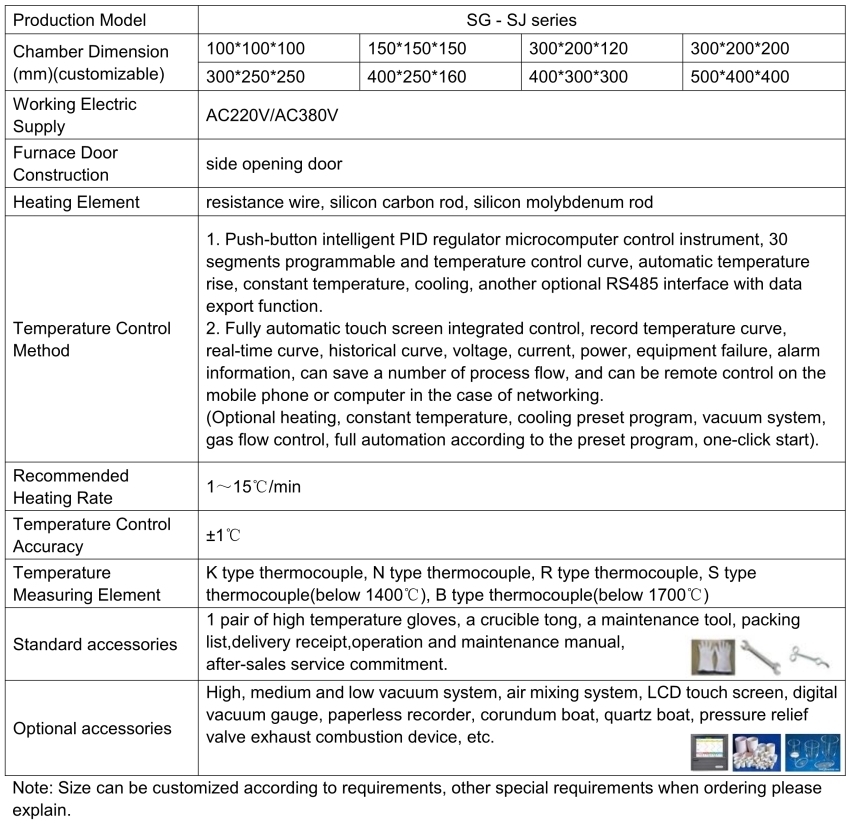

SJ Sintering Furnace

SJ Sintering Furnace

SJL Elevator Type Furnace

SJL Elevator Type Furnace