SG-THL900 box-type vacuum atmosphere furnace uses high-quality resistance wire as heating element, adopts double shell structure and intelligent temperature control system, phase-shifting trigger and silicon controlled control; furnace gallbladder adopts 310S stainless steel with high temperature resistance, pressure resistance and oxidation resistance; double shell structure, with air-cooling and water-cooling system, can quickly cool down, and furnace door is equipped with circulating water cooling to prevent the sealing ring from aging too fast, so as to ensure the furnace. Reliable sealing of doors and bladders.

Main uses and scope of application:

It can be used in vacuum or atmospheric heat treatment of electronic components, new materials and powder materials. Also used in metallurgy, machinery, light industry, commodity inspection, institutions of higher learning and scientific research departments, industrial and mining enterprises electronic ceramic products pre-firing, sintering, brazing and other processes.

Main functions and characteristics:

1. The furnace gallbladder is made of 310S stainless steel with high temperature resistance, pressure resistance and oxidation resistance. It has good mechanical properties, no distortion at high temperature and oxidation resistance, and no oxide layer falls off after repeated recycling.

2. Vacuum can be pumped and various protective atmosphere can be introduced (except inflammable, explosive and highly corrosive gases).

3. The furnace uses alumina polycrystalline fiber material, which has good thermal insulation, durability, high tensile strength, no impurities, high purity, and better energy-saving effect than domestic fiber materials.

4. The heating element adopts high quality alloy wire OCr27Al7Mo2, which has uniform and stable heating and long service life. The alloy wire is embedded in the furnace and is heated externally, thus avoiding the possibility of contacting with the furnace gallbladder and is safe and reliable.

5. Overvoltage automatic relief, over-temperature alarm and power failure, leakage protection, safe and reliable operation;

6. Our software devices are connected with computers through 485 or USB interface, which can realize remote control, real-time tracking, history recording and report output of single or multiple electric furnaces, and can install paperless recording device to realize data storage and output.

7. The vacuum system, inflation system and temperature control system can be programmed by touch screen operation. The operation is simple, convenient and accurate.

Technical parameters:

Product model

SG-THL900

Furnace size (mm)

(customizable)

100*100*100

150*150*150

300*200*120

300*200*200

Furnace size (mm)

(customizable)

300*250*250

350*250*200

400*300*300

500*400*400

Working power supply

(According to customer requirements)

AC 380V 50/60Hz or AC 220V 50/60Hz

Furnace door structure

Side opening type

Heating element

High Quality Resistance Wire (OCr27Al7Mo2)

working temperature

Less than 850 degrees centigrade

Maximum temperature

900 C

temperature control

Intelligent PID control, micro-computer control, 30-section programmable temperature control curve, without duty (automatic heating, constant temperature, cooling)

heating rate

1~15 C /min

control accuracy

+ 1 c

vacuum degree

(Customer optional)

- 0.1 MPa (Standard Matching)

Thermometric element

(Customer Selection)

S-type thermocouple

Standard accessories

One pair of high temperature gloves, one crucible pliers, one set of maintenance tools, packing list, delivery receipt, operation and maintenance instructions, and after-sales service commitment.

Optional Accessories

High, medium and low vacuum systems, paperless recorders, corundum crucibles, quartz crucibles, etc.

Note: Furnace size can be customized according to requirements. Please specify when ordering other special requirements.

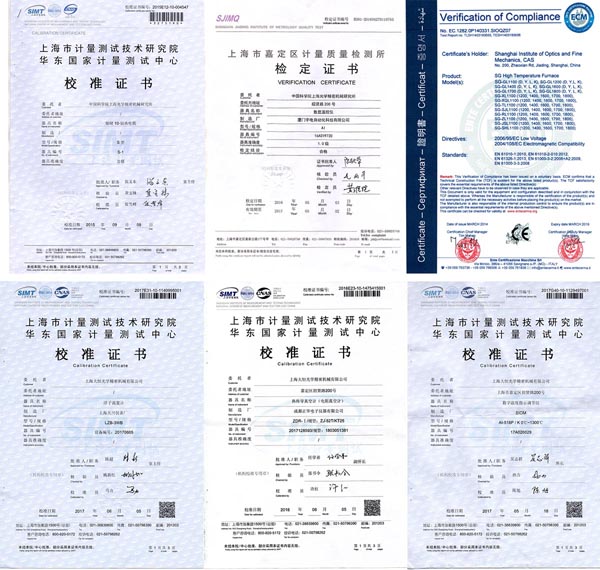

Quality Advantages of Experimental Furnace of Shanghai Institute of Optical Precision Machinery, Chinese Academy of Sciences:

I. Furnace Shell and Furnace

1. Double-layer high-quality carbon steel plate, surface rust-proof and high-temperature paint treatment;

2. High temperature furnace with alumina polycrystalline fibers is beautiful and energy-saving.

II. Electrical appliances and temperature control

1. All the electronic components of Delicious brand and SCR are originally made in Japan or Germany.

2. To ensure safe and efficient use, imported copper isolation transformer is adopted.

3. Temperature Control and Detection

Rhodium monoplatinum (S type) is less than 1500 C.

Bi-platinum rhodium (B type) is less than 1800 C.

Senior engineer, master of engineering and doctor of Shanghai Institute of Optics and Precision Machinery, Chinese Academy of Sciences can select the experimental furnace for your company and research institute, and senior designers can work together to design the high temperature furnace.