Product Introduction:

The stainless steel vacuum atmosphere furnace utilizes resistance wire as its heating element, adopting an external heating method. It features a temperature control system regulated by a silicon controlled rectifier (SCR). The furnace chamber is constructed with high-temperature and pressure-resistant 310S stainless steel. The double-shell structure is equipped with both air-cooling and water-cooling systems for rapid cooling. The furnace door is also water-cooled to prevent premature aging of the sealing ring, ensuring a reliable seal between the door and the furnace chamber.

Main Applications And Scope:

This furnace is designed to meet the requirements of heat treatment experiments under high-temperature and high-humidity conditions. It is applicable to the heat treatment processes of electronic components, advanced materials, and powder materials under vacuum or controlled atmospheres. It is also used in metallurgy, machinery, light industry, commodity inspection, higher education institutions, research departments, and industrial and mining enterprises for processes such as pre-sintering, sintering, and brazing of electronic ceramic products.

Main Functions And Features:

1. Equipped with a steam generator, it allows steam to be introduced into the furnace chamber, fulfilling customers' needs for heat treatment experiments under high-temperature and high-humidity conditions.

2. The furnace chamber is made of high-temperature and pressure-resistant 310S stainless steel, which exhibits excellent mechanical properties, resists deformation at high temperatures, and does not experience oxide layer peeling after multiple uses.

3. Capable of vacuum pumping and introducing various protective atmospheres (excluding flammable, explosive, toxic, harmful, and highly corrosive gases).

4. The furnace lining is made of poly-crystalline alumina fiber material, which offers excellent thermal insulation, durability, high tensile strength, purity without impurity balls, and superior energy-saving performance compared to domestic fiber materials.

5. The heating element uses resistance wire, providing uniform and stable heating with a long service life. The alloy wire is embedded in the furnace lining, adopting an external heating method to avoid contact with the furnace chamber.

6. Features automatic pressure relief in case of over-pressure, high-temperature alarm with power-off function, and leakage protection for reliable operation.

7. The software equipment can be connected to a computer via 485 or USB interface, enabling remote control, real-time tracking, historical recording, and report output for single or multiple furnaces. It can also be equipped with a paperless recording device for data storage and output.

8. Optionally, a touchscreen operation interface is available for programming the vacuum system, gas filling system, and temperature control system, providing simple and accurate operation.

GL Tube-Type Furnace

GL Tube-Type Furnace

XL Box-Type Furnace

XL Box-Type Furnace

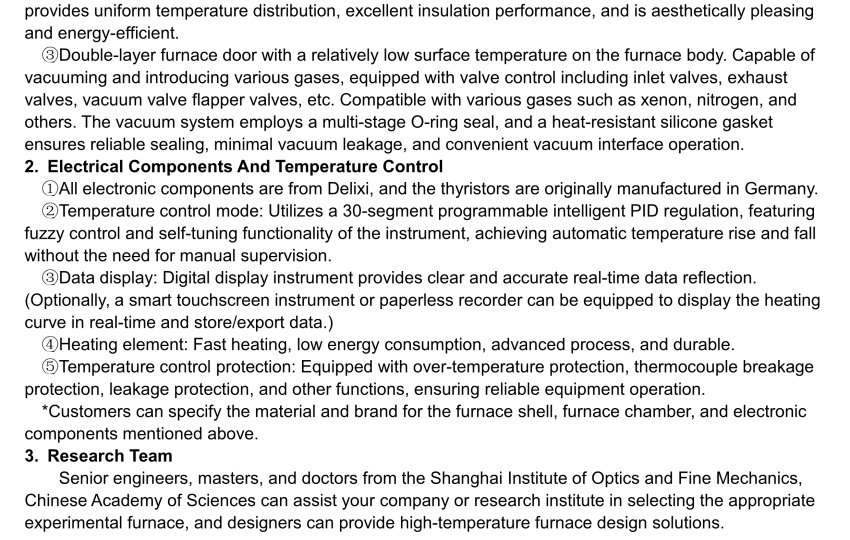

XQL Atmosphere Furnaces

XQL Atmosphere Furnaces

JSL Pit-Type Furnace

JSL Pit-Type Furnace

SJ Sintering Furnace

SJ Sintering Furnace

SJL Elevator Type Furnace

SJL Elevator Type Furnace